Blog

- Home

- Blog

- Optical ODM service

- Choosing Between Lenses and Reflectors: Differences and Considerations

Choosing Between Lenses and Reflectors: Differences and Considerations

August 02,2024

In lighting design, the choice between lenses and aluminum reflectors plays a crucial role. These components not only affect the light distribution but also impact the durability, cost, and overall design process of the fixture. Below, we’ll explore the differences between lenses and reflectors based on material, cost transparency, design applications, and more.

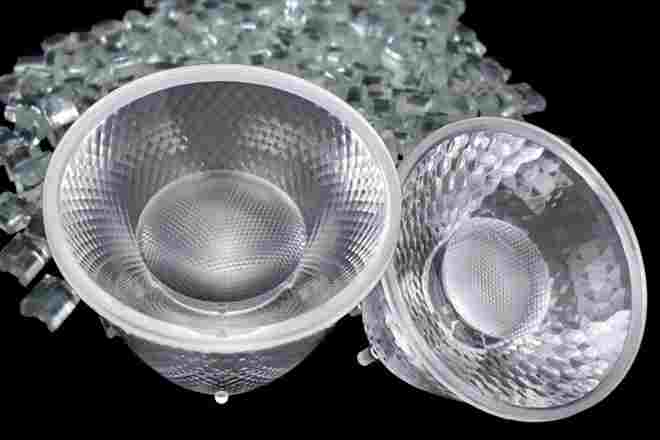

1. Lens Material Selection

Professional lenses are typically made of PMMA (Polymethyl methacrylate) or PC (Polycarbonate), both known for their excellent light transmission and durability. However, some manufacturers may use lower-quality, non-heat-resistant transparent plastic as substitutes for PMMA or PC. In high-temperature environments, such inferior materials can cause the lens to yellow or deform over time, leading to safety concerns. Therefore, selecting high-quality, heat-resistant materials is essential for long-term reliability.

2. Advantages of Aluminum Reflectors

Aluminum reflectors offer significant advantages in terms of mold costs and development time. Compared to lens molds, which are expensive and time-consuming to develop, aluminum reflector molds are quicker and more cost-effective to produce. Additionally, aluminum reflector materials have transparent pricing, as aluminum sheet costs are publicly listed by the London Metal Exchange (LME), ensuring price stability and transparency. In contrast, heat-resistant 5VA-grade PMMA or PC lenses are less commonly used, resulting in higher minimum order quantities (MOQ) and less transparent pricing, with the added risk of material mixing issues.

3. Design Space and Optical Requirements

In small spaces, lenses excel due to their ability to narrow the beam angle, making them ideal for designs that require concentrated light. In the past, many lighting designs favored lenses over aluminum reflectors to enhance optical performance. However, with modern lighting trends emphasizing anti-glare functionality, reflectors are becoming the preferred choice. By recessing the light source into the fixture and using different designs and surface treatments on the trim, glare can be significantly reduced, improving user comfort. Reflectors, therefore, serve not only an optical purpose but also play a key role in the aesthetic design of fixtures.

4. The Shift from Lenses to Reflectors

As demand for anti-glare designs increases, the use of lenses in modern lighting products is gradually declining. While lenses still offer advantages in concentrated light and confined spaces, the structural and design flexibility of aluminum reflectors has made them the preferred choice. Especially in products focused on improving visual comfort, reflectors outperform lenses in both function and appearance.

With Amline, we provide comprehensive solutions, offering both PMMA and PC lenses as well as aluminum reflectors. We ensure complete material certifications, comprehensive optical designs, and consistent quality, making us the reliable choice for your lighting design needs. Whether you're focusing on beam angle precision or anti-glare functionality, Amline's products deliver top-tier performance across all aspects of your lighting project.

1. Lens Material Selection

Professional lenses are typically made of PMMA (Polymethyl methacrylate) or PC (Polycarbonate), both known for their excellent light transmission and durability. However, some manufacturers may use lower-quality, non-heat-resistant transparent plastic as substitutes for PMMA or PC. In high-temperature environments, such inferior materials can cause the lens to yellow or deform over time, leading to safety concerns. Therefore, selecting high-quality, heat-resistant materials is essential for long-term reliability.

|

|

2. Advantages of Aluminum Reflectors

Aluminum reflectors offer significant advantages in terms of mold costs and development time. Compared to lens molds, which are expensive and time-consuming to develop, aluminum reflector molds are quicker and more cost-effective to produce. Additionally, aluminum reflector materials have transparent pricing, as aluminum sheet costs are publicly listed by the London Metal Exchange (LME), ensuring price stability and transparency. In contrast, heat-resistant 5VA-grade PMMA or PC lenses are less commonly used, resulting in higher minimum order quantities (MOQ) and less transparent pricing, with the added risk of material mixing issues.

3. Design Space and Optical Requirements

In small spaces, lenses excel due to their ability to narrow the beam angle, making them ideal for designs that require concentrated light. In the past, many lighting designs favored lenses over aluminum reflectors to enhance optical performance. However, with modern lighting trends emphasizing anti-glare functionality, reflectors are becoming the preferred choice. By recessing the light source into the fixture and using different designs and surface treatments on the trim, glare can be significantly reduced, improving user comfort. Reflectors, therefore, serve not only an optical purpose but also play a key role in the aesthetic design of fixtures.

4. The Shift from Lenses to Reflectors

As demand for anti-glare designs increases, the use of lenses in modern lighting products is gradually declining. While lenses still offer advantages in concentrated light and confined spaces, the structural and design flexibility of aluminum reflectors has made them the preferred choice. Especially in products focused on improving visual comfort, reflectors outperform lenses in both function and appearance.

Conclusion

Lenses and reflectors each offer unique advantages in lighting design. Lenses are ideal for applications where concentrated light is needed in confined spaces, while aluminum reflectors provide superior anti-glare functionality and enhance the aesthetic of the fixture. As lighting technology evolves, designers increasingly combine both lenses and reflectors to achieve optimal lighting results. Lenses handle the optical aspects, concentrating the beam, while reflectors reduce glare and contribute to the overall design aesthetic. This approach strikes a balance between technical performance and visual comfort.

With Amline, we provide comprehensive solutions, offering both PMMA and PC lenses as well as aluminum reflectors. We ensure complete material certifications, comprehensive optical designs, and consistent quality, making us the reliable choice for your lighting design needs. Whether you're focusing on beam angle precision or anti-glare functionality, Amline's products deliver top-tier performance across all aspects of your lighting project.